When working with abrasive tooling for metal fabrication, selecting the right angle grinder disc is critical to achieving precision cuts and extending tool longevity. Factors such as disc diameter, grit size, bond type, and rotational speed compatibility all influence cutting efficiency and surface finish quality. In particular, the best angle grinder disc for cutting metal must balance hardness and flexibility to withstand high-temperature friction without compromising structural integrity.

Metallurgists and fabricators alike understand that the right abrasive composition—whether aluminum oxide, zirconia alumina, or silicon carbide—directly affects cutting speed and burr minimization. Navigating these technical considerations can be complex, but mastering them is essential for optimizing performance and safety in metal cutting operations.

Discover which characteristics set apart the best angle grinder disc for cutting metal in the detailed analysis ahead.

Discover the Top Choices to Make Metal Cutting Effortless and Precise

| Image | Product | Price |

|---|---|---|

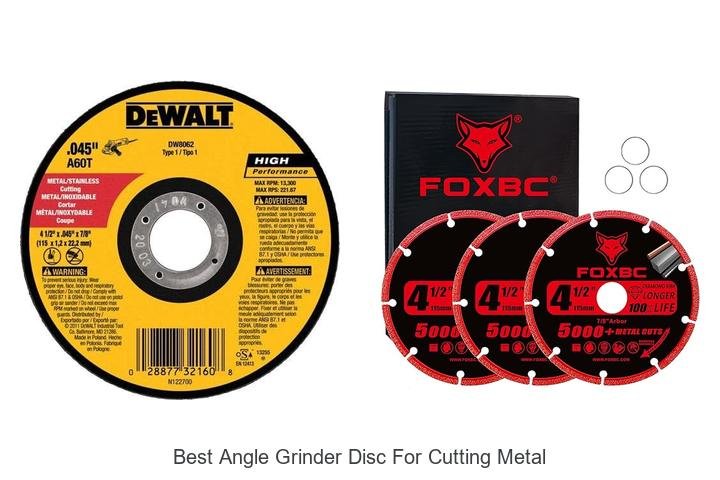

Our Recommended 1  | DEWALT 4-1/2 Inch Cut-Off Wheel, Angle Grinder Cutting Disc, Aluminum | Check Price |

Our Recommended 2  | FOXBC 4-1/2 Inch Diamond Cutting Wheel Metal Cut Off for | Check Price |

Our Recommended 3  | DeWalt DW8062 4-1/2″x.045″x7/8″ Metal Angle Grinder Thin Cutoff Wheel, 10 | Check Price |

1. DEWALT 4-1/2 Inch Cut-Off Wheel, Angle Grinder Cutting Disc, Aluminum

Experience precision and durability with the DEWALT 4-1/2 Inch Cut-Off Wheel, expertly engineered for fast, clean cuts on metal. Designed to deliver exceptional longevity and versatile cutting performance, this angle grinder disc is a trusted choice for professionals and DIY enthusiasts alike.

Featuring Temper Point grains that maintain sharpness longer, this cutting disc offers 50% more life and fewer wheel replacements. Its thin design enables aggressive cutting across carbon steel, stainless, and nickel alloys, while two layers of fiberglass enhance strength and reduce breakage risk under demanding conditions.

Pros

- Long-lasting Temper Point grains provide extended wheel life and consistent sharpness

- Thin 0.045-inch design allows for fast, precise cuts with minimal burrs

- Durable dual-fiberglass construction minimizes breakage, ensuring user safety and reliability

Cons

- Limited to metal cutting applications; not suitable for masonry or other materials

Combining durability, versatility, and efficient cutting action, the DEWALT DW8062B5 is an excellent choice for those seeking the best angle grinder disc for cutting metal. Its robust build and user-friendly design make it a smart investment compared to generic alternatives.

2. FOXBC 4-1/2 Inch Diamond Cutting Wheel Metal Cut Off for

Enhance your metal cutting projects with the FOXBC 4-1/2 Inch Diamond Cutting Wheel, designed for precision and durability. Its diamond rim technology offers superior performance, enabling clean, smooth cuts on various metals while extending the wheel’s lifespan significantly compared to traditional discs.

Constructed with a solid steel body and an electro-plated diamond abrasive edge, this cutting wheel delivers consistent control and minimal dust during dry cutting of metal, rebar, stainless steel, aluminum, and more. The wheel’s reinforced design ensures safety and long-lasting use with minimal downtime.

Pros

- Up to 100 times longer cutting life than standard bonded discs

- Advanced diamond abrasive edge offers precision cutting with less sparks and dust

- Durable solid steel body reduces breakage risk, enhancing user safety

Cons

- Priced higher than some conventional abrasive discs

For professionals and hobbyists alike, the FOXBC diamond cutting wheel stands out by combining unmatched durability with exceptional control and safety. It’s an excellent investment for those seeking reliable and high-performance metal cutting solutions beyond what typical discs offer.

3. DeWalt DW8062 4-1/2″x.045″x7/8″ Metal Angle Grinder Thin Cutoff Wheel, 10

Experience precision and efficiency with the DeWalt DW8062 4-1/2 Thin Cutoff Wheel, engineered specifically for cutting metal with speed and minimal burr. Its slim .

Crafted from a proprietary aluminum oxide grain combination, this 10-pack of cutoff wheels provides aggressive cutting action while maintaining durability. Reinforced with two full sheets of fiberglass, these wheels offer enhanced safety and long-lasting performance on compatible angle grinders, including the DEWALT DCG416B model.

Pros

- Thin .045-inch design enables fast, burr-free metal cutting

- Durable construction with aluminum oxide grain for aggressive and consistent cutting

- Enhanced safety thanks to dual fiberglass reinforcement

Cons

- Manufactured in China, which may concern users seeking locally made products

The DeWalt DW8062 cutoff wheels deliver excellent cutting performance with durability and safety at an affordable price, making them a reliable choice among the best angle grinder discs for cutting metal on the market. Ideal for professionals demanding quality and consistency in their cutting tools.

4. 4 1/2 Cut Off Wheel Angle Grinder Cutting Disc for

Experience superior metal cutting performance with the 4 1/2 Cut Off Wheel Angle Grinder Cutting Disc. Engineered to deliver precise, efficient cuts on metal and stainless steel, this disc enhances your angle grinder’s capabilities while ensuring durability and safety for rigorous metalworking tasks.

Crafted from a dual alumina blend combining white and brown alumina, these ultra-thin 045-inch discs offer fast cutting speeds and reduced material waste. Rated for speeds up to 13,300 RPM, each reinforced wheel withstands tough projects, making them ideal for steel pipes, rebar, and various cutting applications.

Rated for speeds up to 13,300 RPM, each reinforced wheel withstands tough projects, making them ideal for steel pipes, rebar, and various cutting applications.

Pros

- High-performance cutting suitable for metal and stainless steel

- Durable dual alumina composition improves longevity and cutting speed

- Thin 0.045″ design minimizes material waste and provides smooth cuts

- Reinforced construction enhances wear resistance for heavy-duty cutting

- Cost-effective 10-pack ensures availability for frequent use

Cons

- May require careful handling due to ultra-thin design to avoid breakage

Offering excellent cutting power and durability, these PUOPOSTY angle grinder discs stand out among similar products in both performance and value. Their specialized alumina blend and slim profile make them a top choice for professionals and DIY enthusiasts seeking the best angle grinder disc for cutting metal efficiently and cleanly.

5. SALI 50 Pack Cut Off Wheel 4 1/2 Inch Cutting

Upgrade your metal cutting tasks with the SALI 50 Pack Cut Off Wheel 4 1/2 Inch Cutting discs, designed for precision and durability. These thin, high-performance wheels deliver fast, burr-free cuts, making them an excellent choice for professionals and DIY enthusiasts seeking reliable and efficient results.

Each pack includes 50 cutting wheels sized 4-1/2-inch by .045-inch thickness, compatible with all standard 4-1/2 inch angle grinders featuring a 7/8-inch arbor.

Pros

- Thin .045-inch design ensures fast, burr-free cuts for clean workpieces

- Durable double fiberglass mesh reinforcement boosts safety and longevity

- Proprietary aluminum oxide grit delivers aggressive, long-lasting cutting power

Cons

- Not suitable for cutting materials other than metal or stainless steel

Offering excellent value and performance compared to similar brands from major retailers, the SALI Cut Off Wheels stand out for their durability and consistent cutting efficiency. Ideal for heavy-duty use, these discs are a smart investment for anyone looking to enhance their metalworking toolkit.

6. 10 Pack 4 1/2 in Cut Off Wheel Cutting Wheels

Discover precision and efficiency with the 10 Pack 4 1/2 in Cut Off Wheel Cutting Wheels, expertly designed for fast, clean cuts on various metals. Perfect for professionals and DIY enthusiasts alike, these discs offer enhanced durability and compatibility with all standard angle grinders, making metal cutting tasks smoother and more reliable.

Each cutting wheel features a thin 1/64-inch design crafted from ultra-fine aluminum oxide abrasive, providing exceptional cutting accuracy and speed. With built-in air holes to dissipate heat, these discs maintain peak performance without damage. Ideal for carbon steel, stainless steel, pipes, iron, and copper, they meet industrial-grade cutting demands with safety and precision.

Pros

- High cutting efficiency with a thin 1/64-inch wheel suitable for precise metal work

- Compatible with all 4 1/2-inch angle grinders operating up to 13,300 RPM for versatile use

- Durable construction with abrasive particles and heat-dissipating air holes to prevent overheating

Cons

- Not recommended for cutting aluminum alloys, limiting application on some softer metals

Offering great value and performance, this 10-pack of cutting wheels stands out as a cost-effective choice for metal cutting projects, particularly when compared to thicker or less heat-resistant alternatives. Its balance of precision, durability, and safety features makes it an excellent addition to any professional toolkit.

7. EZARC Diamond Cutting Wheel 4 1/2 x 7/8 Inch for

Experience unmatched precision and durability with the EZARC Diamond Cutting Wheel 4 1/2 x 7/8 Inch, engineered to excel in metal cutting tasks. Designed for professionals and DIY enthusiasts alike, this cutting disc combines advanced diamond technology with industrial-grade construction for efficient, reliable performance on a variety of metals.

Crafted with fine diamond grit, the EZARC cutting wheel offers over 5,000 cuts with superior longevity compared to bonded wheels. Its solid steel body enhances safety by minimizing shattering risks, while maintaining its diameter for consistent, precise cuts on metal, rebar, alloy steel, aluminum, and more.

Pros

- Durable diamond technology delivers 100 times longer life than typical bonded wheels

- Solid steel wheel body reduces shatter risk, ensuring safer operation and cleaner work environments

- Maintains original diameter throughout use for accurate and controlled cutting performance

Cons

- Premium quality comes at a slightly higher initial cost compared to standard abrasive discs

For those seeking the best angle grinder disc for cutting metal, the EZARC Diamond Cutting Wheel offers exceptional value, outlasting traditional wheels and delivering faster, cleaner cuts while prioritizing safety. Its performance and longevity make it a smart investment for any metal cutting project.

8. 4 1/2 Inch Cut Off Wheel Diamond Cutting Wheel 4

Experience exceptional cutting performance with the 4 1/2 Inch Cut Off Wheel Diamond Cutting Wheel, designed for precision and durability in metalwork. Engineered for both professional and DIY use, it offers unmatched efficiency and safety, making it the ideal choice for your angle grinder projects.

Featuring a 4-1/2 inch diameter with a robust steel core and premium diamond-coated edges, this cutting wheel delivers clean, precise cuts on metal materials such as steel, rebar, iron, and INOX. Its ultra-thin 2mm design reduces resistance while enhancing sharpness and control, supported by superior heat and dust dissipation for improved longevity and workspace cleanliness.

Pros

- Industrial-grade diamond brazing technology ensures long-lasting, heat-resistant cutting performance.

- Ultra-thin 1.2mm blade thickness minimizes cutting resistance for greater precision and control.

- Solid steel body reduces breakage risks, increases safety, and lowers operational noise.

- Compatible with all angle grinders featuring a standard 7/8″ arbor size.

- Produces fewer sparks, no dust, and no unpleasant odors, resulting in a cleaner, safer work environment.

- Extends tool life up to 120 times longer than conventional discs, boosting productivity.

Cons

- Higher upfront cost compared to traditional abrasive discs, though compensated by longevity.

Offering a superior balance of durability, precision, and safety, the Revvstark Diamond Cutting Wheel stands out as a cost-effective solution for demanding metal cutting tasks. Its industrial-grade construction and thoughtful design deliver better performance and cleaner cuts compared to standard abrasive wheels, making it a smart investment for quality-conscious users.

9. Merryland Cut Off Wheel 4 1/2 inch for Angle Grinder,

Upgrade your metal cutting projects with the Merryland Cut Off Wheel 4 1/2 inch for Angle Grinder, offering precision and durability. Engineered for smooth, fast, and safe cuts, this disc excels in handling various metals, making it a must-have for professionals and hobbyists alike.

Crafted from German Phenolic Resin and refined White Corundum, this ultra-thin 045-inch cutting wheel features a reinforced fiberglass mesh structure, ensuring longevity and safety at speeds up to 13,300 RPM.

Pros

- Exceptional durability from German Phenolic Resin and White Corundum composition

- Safe and reliable reinforcement with dual-layer fiberglass mesh and MPA certification

- Versatile use on a wide range of materials including stainless steel and plastics

Cons

- Limited to angle grinders with 4.5″ diameter and 7/8″ bore compatibility

Offering a perfect balance of precision, safety, and versatility, Merryland’s cut-off wheels deliver professional-grade performance at an affordable price. Compared to other discs in the market, their superior construction provides less wear and a smoother cut, making it an excellent investment for all your metalworking needs.

10. FOXBC 4-1/2 Inch Cut Off Wheel Discs for Angle Grinder,

Discover powerful precision with the FOXBC 4-1/2 Inch Cut Off Wheel Discs, expertly engineered for cutting metal. These discs elevate angle grinder performance, offering fast, clean cuts on steel, stainless, and other tough metals while maintaining durability and safety during demanding tasks.

Designed with premium aluminum oxide and dual fiberglass reinforcement, each wheel delivers exceptional strength and longevity. The thin kerf design reduces resistance to maximize tool efficiency, making it ideal for both cordless and corded angle grinders. Equipped with a 7/8 arbor and built for speeds up to 13,280 RPM, these discs ensure versatile use in tight or hard-to-reach spaces.

Equipped with a 7/8 arbor and built for speeds up to 13,280 RPM, these discs ensure versatile use in tight or hard-to-reach spaces.

Pros

- Durably constructed with two layers of fiberglass for enhanced safety and reduced breakage risk.

- Thin kerf design allows for fast, clean cuts with minimal burr formation, improving overall productivity.

- Compatible with a wide range of angle grinders, suitable for cutting various metal types including stainless steel and cast iron.

Cons

- Available only in packs of 50, which may be more than needed for casual users.

Offering excellent value compared to smaller packs from major retailers, these cut-off wheels provide reliable quality and performance. For metal cutting tasks requiring durability and precision, FOXBC’s angle grinder discs stand out as an efficient, cost-effective choice.

Top Angle Grinder Discs for Cutting Metal: Buying Guide

Disc composition and grit

Choosing the right disc composition and grit is essential when selecting an angle grinder disc for cutting metal to ensure optimum performance and durability. Discs made from common materials such as aluminum oxide offer reliable cutting power and versatility, while those with zirconia composition tend to provide enhanced toughness and longer life, especially when dealing with tougher metals. The grit level also plays a vital role; coarser grits are better suited for rough cuts that require faster material removal, whereas finer grits are ideal for precision cutting where smoother edges are desired.

The grit level also plays a vital role; coarser grits are better suited for rough cuts that require faster material removal, whereas finer grits are ideal for precision cutting where smoother edges are desired. Additionally, the material composition impacts heat resistance, which is important to prevent the disc from overheating and wearing out prematurely during intensive tasks. By considering the balance between these factors based on your specific use case, you can make an informed choice that maximizes both efficiency and safety in metal cutting projects.

Durability and performance

When selecting your topic’s reference keyword, focusing on Durability and performance is essential to ensure a reliable and efficient cutting experience. Heat resistance and efficiency during cutting play crucial roles, as high temperatures generated by friction can quickly degrade an inferior disc, causing it to wear out faster or even become unsafe. Choosing a disc made from quality materials with good heat resistance helps maintain optimal cutting speed and precision while minimizing downtime.

Additionally, resistance to disc wear and chipping is important for safety and longevity. A durable disc withstands the rigors of metal cutting without breaking down prematurely, ensuring consistent performance over time.

Paying attention to customer reviews and brand reliability can provide valuable insights into how well different discs hold up under real-world conditions. Trusted brands often invest more in quality control and use advanced materials that enhance both durability and cutting efficiency.

Material compatibility

When selecting the best angle grinder disc for cutting metal, it is essential to consider the types of metals you plan to work with to ensure optimal performance and safety. Different metals, such as steel, aluminum, and stainless steel, vary in hardness, requiring discs with specific abrasiveness levels to achieve clean and efficient cuts. For instance, a disc with higher abrasiveness is better suited for harder metals like stainless steel, while less abrasive discs work well with softer metals like aluminum to prevent excessive wear.

Understanding how the disc’s abrasiveness corresponds to the metal’s hardness helps avoid common issues such as premature disc wear or uneven cutting. Using a disc that is not compatible with the metal type can lead to damage not only to the disc itself but also to the grinder and the workpiece.

Therefore, it is advisable to check the manufacturer’s recommendations and opt for discs designed specifically for your intended metal, which will prolong the disc’s lifespan and improve cutting precision. Paying close attention to these compatibility factors allows beginners to select a cutting disc that delivers reliable results while maintaining safety throughout the cutting process.

Disc size and thickness

When selecting discs for metal cutting tasks, it’s important to consider the standard diameters available, as these typically range based on the angle grinder model. Choosing the correct size ensures compatibility and optimal performance, allowing you to make clean and efficient cuts. The thickness of the cutting disc plays a crucial role in both its durability and cutting speed; thinner discs usually provide faster cuts with less material removal but may wear out more quickly, while thicker discs offer greater longevity but can produce slower cuts and wider kerfs.

Matching the disc size with your angle grinder’s specifications not only enhances safety but also prevents undue strain on the tool, ensuring smooth operation and reducing the risk of disc damage. Careful attention to these factors will help you achieve better results whether you are involved in light-duty tasks or more demanding metal cutting projects.

Cost and value

When selecting the right grinding disc for metal cutting tasks, it is important to consider what quality and features you truly need to ensure both efficiency and safety. Discs that offer durability and high-speed performance tend to come within a moderate to higher price range, reflecting their ability to handle tough materials and prolonged use.

Finding a balance between how much you spend and the performance required for your projects will help you make a practical choice without overspending. Additionally, checking for the availability of replacement discs is crucial, as this affects the longevity and convenience of your tool. Reliable brands often provide warranties that add peace of mind, ensuring that your investment is protected against manufacturing defects or premature wear.

Keeping these factors in mind will help you select a disc that not only fits your budget but also meets the demands of your metal cutting tasks efficiently.

Speed rating and safety considerations

When selecting the best angle grinder disc for cutting metal, it is essential to consider the maximum RPM compatibility with your angle grinder to ensure optimal performance and prevent disc failure. Discs are designed to operate safely within specific speed limits, so matching the disc’s maximum RPM rating to your grinder’s speed is crucial.

To maintain safety during use, always wear appropriate protective gear such as gloves, safety glasses, and a face shield, and make sure the disc is properly installed following the manufacturer’s instructions. This not only enhances safety but also improves cutting precision and extends the life of both the disc and the angle grinder.

People Also Asked

What Type Of Angle Grinder Disc Is Best For Cutting Metal?

The best type of angle grinder disc for cutting metal is a thin, abrasive cutoff wheel made from aluminum oxide or silicon carbide. These discs are specifically designed to efficiently cut through metal while providing clean and precise cuts.

How Do I Choose The Right Disc Size For Cutting Metal With An Angle Grinder?

To choose the right disc size for cutting metal with an angle grinder, select a disc that matches the grinder’s specified diameter and is suitable for metal cutting, typically between 4.5 to 9 inches. Always ensure the disc’s thickness and material compatibility align with your cutting needs for safety and efficiency.

Can I Use A Diamond Blade Disc For Cutting Metal With An Angle Grinder?

While diamond blade discs are designed primarily for cutting hard materials like concrete and stone, they are generally not recommended for cutting metal with an angle grinder because metal requires a blade made specifically for metal cutting to ensure safety and effectiveness. For cutting metal, it’s best to use an abrasive cutoff wheel or a blade specifically designed for metal.

How Do I Ensure Safety When Using An Angle Grinder Disc To Cut Metal?

To ensure safety when using an angle grinder disc to cut metal, always wear appropriate personal protective equipment such as safety goggles, gloves, and ear protection. Additionally, secure the workpiece firmly, use the correct disc for metal cutting, and follow the manufacturer’s guidelines while maintaining a firm grip and proper posture.

What Materials Are Angle Grinder Discs Made Of For Cutting Metal?

Angle grinder discs for cutting metal are typically made from abrasive materials such as aluminum oxide or zirconia alumina, bonded with resin. These materials provide the necessary hardness and durability to efficiently cut through metal surfaces.

Conclusion

In summary, the best angle grinder disc for cutting metal combines durability, precision, and safety. Look for discs made from high-quality abrasive materials like aluminum oxide or zirconia, with a suitable thickness for metal cutting. Always choose the right size that fits your grinder and prioritize discs with strong bonding for long-lasting performance.

Proper use ensures efficient, clean cuts every time.

Leave a Reply